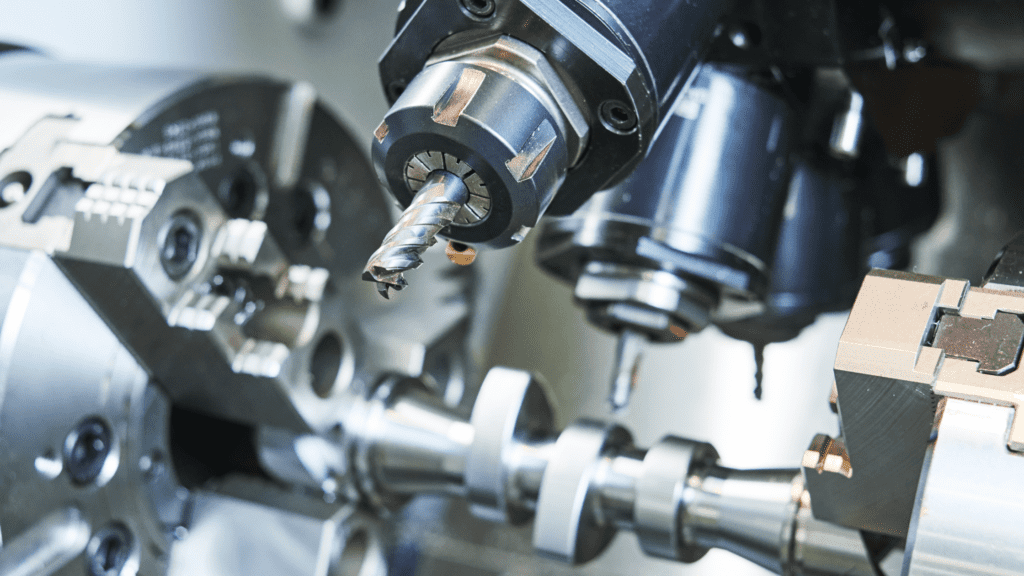

Embark on a journey into the world of Computer Numerical Control (CNC) with our comprehensive guide to G-code. Discover how G-code serves as the language of CNC machines, guiding them through precise movements and actions. From the basics of G-code commands to writing your first program, we’ll demystify this essential aspect of CNC machining.

Introduction to G-code

What is G-code?

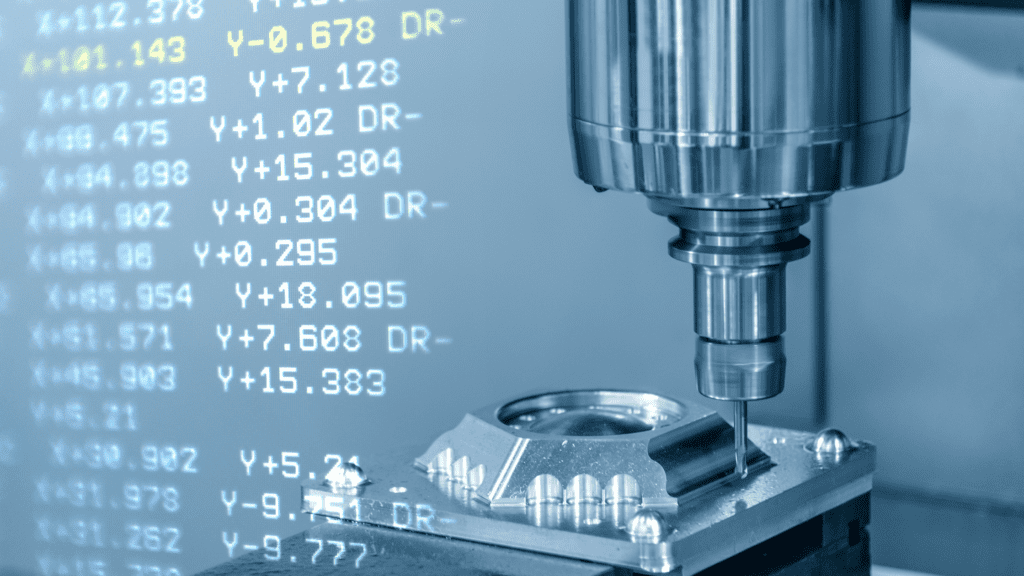

If you’ve ever wondered how Computer Numerical Control (CNC) machines know exactly what to do, the answer lies in G-code. G-code is the language that CNC machines understand. It’s a set of instructions that tells the machine how to move, where to cut, and what path to follow. Think of it as the blueprint for CNC operations. Each line of G-code provides specific directions, ensuring precise movements and actions. Without G-code, CNC machines would be like a car without a driver – powerful but directionless.

The Basics of G-code Commands

At its core, G-code consists of commands that guide the CNC machine. These commands are simple yet powerful. For instance, G01 is used for a straight-line movement, while G02 and G03 are used for clockwise and counterclockwise arcs, respectively. Each command is followed by coordinates that specify where the machine should move. It’s like giving the machine a set of GPS coordinates to follow.

Let’s break down a simple G-code command: G01 X10 Y20. This tells the CNC machine to move in a straight line to the coordinates X10 and Y20. Sounds simple, right? But this simplicity is what makes G-code so effective. By combining these basic commands, you can create intricate designs and precise cuts.

Writing Your First G-code

Writing G-code might seem intimidating at first, but it’s easier than you think. You don’t need to be a coding expert to get started. The key is understanding the basic commands and how they work together. Start with simple tasks, like moving the machine from one point to another. As you gain confidence, you can tackle more complex projects.

For example, let’s write a basic G-code program to draw a square. The commands would look something like this:

G01 X0 Y0 (Start at origin)

G01 X10 Y0 (Move to 10,0)

G01 X10 Y10 (Move to 10,10)

G01 X0 Y10 (Move to 0,10)

G01 X0 Y0 (Return to origin)This simple program tells the CNC machine to draw a square by moving to each corner in turn. Practice writing and running basic G-code programs like this to build your skills.

Tools to Help You Learn G-code

Don’t worry if you’re not ready to dive into writing G-code from scratch. There are plenty of tools to help you along the way. Many CAD (Computer-Aided Design) programs can generate G-code automatically based on your designs. Programs like Fusion 360, SolidWorks, and AutoCAD are popular choices. These tools translate your design into G-code, so you don’t have to write each line manually.

There are also numerous online resources and tutorials available. Websites, forums, and video tutorials can provide valuable insights and tips. These resources are great for learning the basics and picking up advanced techniques as you progress.

Debugging and Testing G-code

Like any programming language, G-code can have errors. But don’t worry – debugging G-code is part of the learning process. When you run a program, pay close attention to how the machine moves. If something doesn’t look right, check your G-code for typos or logical errors.

Many CNC machines come with simulation software that lets you test your G-code before running it on the machine. This software can show you a virtual preview of the machine’s movements, helping you spot mistakes without risking damage to the machine or material.

Another useful tip is to start with low speeds and shallow cuts when testing new G-code. This approach gives you more control and reduces the risk of errors causing significant problems. As you become more confident in your G-code, you can increase the speed and depth of cuts.

Advanced G-code Techniques

Once you’re comfortable with the basics, you can explore more advanced G-code techniques. For example, you can use loops and subroutines to repeat certain actions, saving you time and effort. Conditional statements can make your G-code programs more dynamic, allowing the machine to make decisions based on specific conditions.

You can also learn about tool changes and how to manage different tools within a single G-code program. This knowledge is crucial for more complex machining tasks that require multiple tools.

Another advanced technique is the use of coordinate transformations. These commands can rotate or scale your entire G-code program, making it easier to work with different orientations and sizes.

Real-World Applications of G-code

Understanding G-code isn’t just about making your CNC machine run. It opens up a world of possibilities for creativity and precision in manufacturing. G-code is used in a variety of industries, from aerospace and automotive to healthcare and consumer electronics.

For example, in the aerospace industry, G-code enables the production of intricate, high-precision components that are essential for aircraft performance. In healthcare, G-code is used to create custom prosthetics and implants with exact specifications, improving patient outcomes.

Even in everyday products, G-code plays a crucial role. The smartphone in your pocket, the car you drive, and the appliances in your home all benefit from the precision and efficiency that G-code provides.

In the world of Computer Numerical Control (CNC), G-code is the unsung hero. It’s the language that brings your designs to life, guiding CNC machines with precision and accuracy. While it might seem complex at first, learning G-code is an achievable and rewarding endeavor. By mastering G-code, you’ll unlock the full potential of your CNC machine, allowing you to create intricate designs and high-quality products with ease.

Whether you’re a hobbyist or a professional, understanding G-code is a valuable skill that can enhance your capabilities and open up new opportunities. So, dive in, start writing some G-code, and watch your CNC machine bring your creations to life.

Essential Software for CNC Enthusiasts

Computer-Aided Design (CAD) Software

When it comes to Computer Numerical Control (CNC) machining, Computer-Aided Design (CAD) software is your starting point. This software helps you create detailed 2D or 3D models of the parts you want to produce. Think of it as the digital sketchpad where your ideas come to life. Popular CAD software options include AutoCAD, SolidWorks, and Fusion 360. These programs offer a range of tools for designing everything from simple shapes to complex assemblies.

Using CAD software is like having a magical drawing board where you can tweak designs to your heart’s content. You can zoom in for fine details or view your project from every angle. Plus, CAD software often includes libraries of standard parts and components, making it easier to design your project. You’ll find yourself experimenting with different designs and improving your skills with every project you undertake.

Computer-Aided Manufacturing (CAM) Software

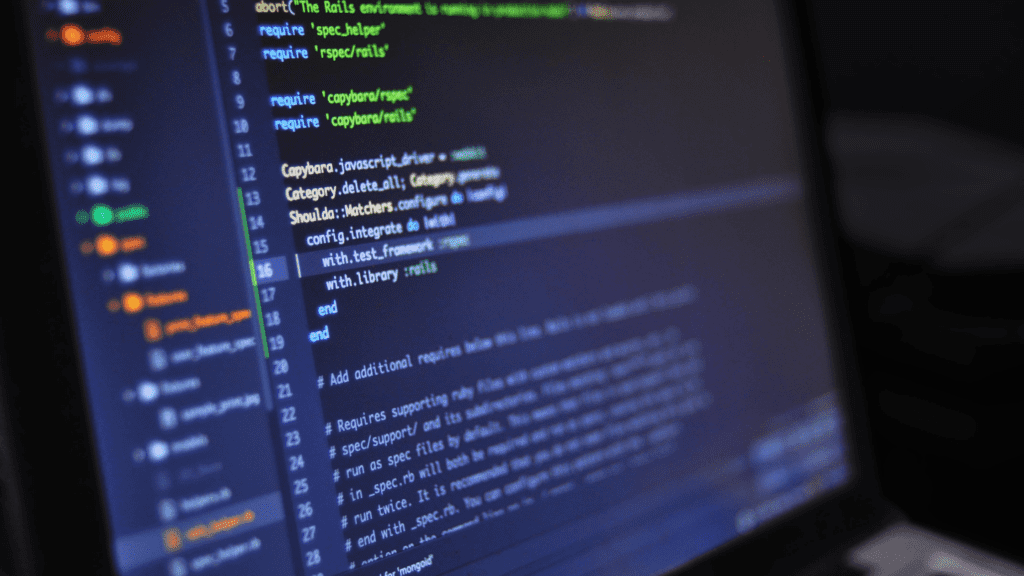

Once your design is ready, it’s time to move to Computer-Aided Manufacturing (CAM) software. CAM software takes your CAD design and translates it into the G-code that your CNC machine understands. This is where the magic happens. Programs like Mastercam, Fusion 360, and HSMWorks are popular choices. They help you generate toolpaths, which are the routes your CNC machine will follow to create your part.

CAM software is incredibly user-friendly. You’ll input your design, select your tools, and set parameters like cutting speed and depth. The software then simulates the machining process, showing you how the machine will cut your material. This visual preview is invaluable, helping you catch potential issues before you start the actual machining. It’s like having a dress rehearsal for your CNC project, ensuring everything runs smoothly when it’s showtime.

Simulation and Verification Tools

Before you let your CNC machine loose on an expensive piece of material, you want to be sure everything is perfect. That’s where simulation and verification tools come into play. Software like VERICUT and NC Simul allows you to simulate the entire machining process in a virtual environment. This step is crucial for detecting any collisions or errors in your G-code that could damage your machine or ruin your workpiece.

Think of simulation software as a safety net. It catches mistakes before they become costly problems. You’ll watch your virtual CNC machine go through the motions, ensuring that every cut is precise and accurate. This added layer of verification gives you peace of mind, knowing that your project will come out exactly as planned. It’s like having an extra set of eyes on your work, ensuring everything is just right.

CNC Machine Control Software

Now that your G-code is ready and verified, you need CNC machine control software to run it. This software interfaces directly with your CNC machine, sending the G-code instructions to guide its movements. Common options include Mach3, LinuxCNC, and GRBL. These programs provide an easy-to-use interface for loading your G-code, starting and stopping your machine, and monitoring its progress.

Using machine control software feels like being at the helm of a spaceship. You have full control over your CNC machine’s operations. You can adjust feed rates, pause the machine, or make on-the-fly adjustments if needed. The software displays real-time feedback, showing you the machine’s status and position. It’s an empowering feeling, knowing you’re in command of such a powerful tool.

Design to Production Workflow

The beauty of CNC machining lies in the seamless workflow from design to production. You start with CAD software to create your design, then use CAM software to generate toolpaths and G-code. Simulation and verification tools ensure your code is error-free. Finally, machine control software runs your G-code on the CNC machine. This integrated process streamlines your work, making Computer Numerical Control (CNC) machining both efficient and enjoyable.

Imagine the satisfaction of seeing your digital designs transformed into physical objects with precision and accuracy. The entire workflow is like a well-choreographed dance, with each piece of software playing its part perfectly. As you become more familiar with each tool, you’ll find your workflow becoming smoother and faster. It’s a rewarding journey, from initial concept to finished product.

Cloud-Based Solutions

In recent years, cloud-based solutions have become increasingly popular in the Computer Numerical Control (CNC) world. Software like Fusion 360 offers cloud-based design and manufacturing tools, allowing you to work from anywhere. You can collaborate with team members in real-time, share designs, and access powerful computing resources without needing a high-end computer.

Cloud-based solutions are a game-changer for flexibility and collaboration. Imagine working on a design at home, then continuing your work seamlessly at the workshop. Your projects are always up to date, and you can easily share your work with others for feedback and collaboration. It’s like having a portable workshop in your pocket, ready to go wherever you are.

Open Source Software

For those on a budget or who enjoy tinkering with software, open-source Computer Numerical Control (CNC) software is a fantastic option. Programs like FreeCAD, LibreCAD, and BlenderCAM offer robust features without the hefty price tag. Open-source software is developed by a community of enthusiasts and professionals, providing a wealth of resources and support.

Using open-source software feels like being part of a global community. You’ll find forums, tutorials, and user groups eager to help you learn and grow. The software is continuously updated with new features and improvements, driven by user feedback and contributions. It’s a collaborative effort, making Computer Numerical Control (CNC) machining accessible to everyone, regardless of budget.

Common Mistakes to Avoid in Computer Numerical Control Machining

Neglecting Proper Tool Selection

One of the most common mistakes in Computer Numerical Control (CNC) machining is neglecting proper tool selection. It’s easy to think that any tool will do the job, but that’s far from true. Choosing the wrong tool can lead to poor quality cuts, increased wear and tear, and even machine damage. Make sure you select the right tool for your material and the specific task at hand. This simple step can save you from a lot of headaches down the line.

Imagine you’re using a hammer when you actually need a screwdriver. That’s what using the wrong CNC tool feels like. Each tool is designed for specific materials and cuts, so taking the time to choose correctly pays off. Your machine will thank you with smoother operations and longer-lasting performance. Plus, you’ll achieve the high-quality results you’re aiming for, every single time.

Skipping Regular Maintenance

Skipping regular maintenance is another big no-no in the world of Computer Numerical Control (CNC) machining. Your CNC machine is a precision instrument, and like any other complex piece of equipment, it needs regular care to function optimally. Neglecting maintenance can lead to unexpected breakdowns, costly repairs, and significant downtime. Keep a maintenance schedule and stick to it diligently.

Think of your CNC machine as a high-performance car. You wouldn’t drive it for years without an oil change, right? Regular maintenance includes cleaning, lubricating moving parts, checking for wear, and replacing worn-out components. By doing this, you ensure your machine runs smoothly and extends its lifespan. It’s a small investment of time that yields substantial rewards in performance and reliability.

Overlooking the Importance of Calibration

Calibration is crucial in Computer Numerical Control (CNC) machining, but it’s often overlooked, especially by beginners. Without proper calibration, even the most sophisticated CNC machine can produce inaccurate and inconsistent parts. Calibration involves adjusting the machine to ensure all its movements are precise and accurate. It’s like tuning a musical instrument to make sure it plays the right notes.

Imagine trying to bake a cake without measuring the ingredients. Skipping calibration is just as risky. Incorrect calibration can lead to parts that don’t fit together, wasted materials, and lots of frustration. Regularly calibrating your machine ensures that your cuts are precise, your parts are consistent, and your projects are successful. It’s a vital step that shouldn’t be ignored.

Ignoring Material Properties

Another common mistake is ignoring the properties of the material you’re working with. Different materials have different characteristics, such as hardness, elasticity, and thermal properties. These factors affect how you should machine the material. Using the same settings for different materials can result in poor finishes, tool wear, and even machine damage.

Imagine you’re trying to cut through butter with the same force you’d use for a block of wood. It just doesn’t work. Pay attention to the material’s properties and adjust your settings accordingly. This includes feed rate, spindle speed, and cutting depth. By tailoring your approach to the material, you’ll achieve better results and extend the life of your tools and machine.

Underestimating the Importance of Workholding

Proper workholding is essential for successful CNC machining, but it’s often underestimated. If your workpiece isn’t securely held in place, it can shift during machining, leading to inaccurate cuts and potential damage to the machine or the workpiece. Using the right clamps, vises, and fixtures ensures that your workpiece stays put throughout the machining process.

Think of workholding as the foundation of a house. Without a solid foundation, everything else is at risk. Take the time to set up your workholding correctly. Make sure the workpiece is firmly secured and that there’s no movement. This step might seem tedious, but it’s crucial for precision and safety. A secure workpiece means clean, accurate cuts and a smoother machining process overall.

Overcomplicating G-code

Overcomplicating G-code is a mistake many newcomers make. While G-code can be complex, you don’t need to make it harder than it is. Start with simple commands and gradually build your skills. Trying to write complex G-code from the get-go can lead to errors and frustration. Remember, simplicity is key.

Imagine trying to write a novel before you’ve mastered basic grammar. Start with straightforward G-code programs and focus on getting them right. As you gain confidence, you can introduce more complexity. By keeping it simple, you’ll avoid unnecessary errors and build a solid foundation for more advanced programming. Your Computer Numerical Control (CNC) projects will benefit from this approach, becoming more efficient and successful.

Not Paying Attention to Safety

Safety should always be a top priority in Computer Numerical Control (CNC) machining, but it’s often overlooked, especially by those eager to get started. Failing to follow safety protocols can lead to serious injuries and accidents. Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. Ensure that emergency stop buttons are easily accessible and that you know how to use them.

Think of CNC machining as operating a powerful and precise tool. Respect its capabilities and potential hazards. Follow safety guidelines, keep your workspace clean and organized, and never bypass safety features. By prioritizing safety, you not only protect yourself but also ensure a smoother and more productive machining process. Remember, a safe work environment is a successful one.

Resources for Learning Computer Numerical Control (CNC)

Online Courses and Tutorials

When diving into the world of Computer Numerical Control (CNC), online courses and tutorials are your best friends. They provide structured learning and expert guidance, making it easier to grasp complex concepts. Platforms like Coursera, Udemy, and LinkedIn Learning offer a range of CNC courses for all skill levels. Whether you’re a complete beginner or looking to enhance your skills, you’ll find courses tailored to your needs.

Imagine having a personal CNC tutor available 24/7. That’s what these online courses offer. You can learn at your own pace, revisit challenging topics, and even earn certificates to showcase your new skills. Many courses include video tutorials, quizzes, and hands-on projects to reinforce learning. So grab your notebook, fire up your computer, and start exploring the vast world of CNC with these online resources.

YouTube Channels

YouTube is a treasure trove of Computer Numerical Control (CNC) knowledge, offering countless free resources for learning. Channels like NYC CNC and Titans of CNC Academy provide in-depth tutorials, project ideas, and tips from industry experts. Watching videos can make complex topics more digestible and fun.

Think of YouTube as your virtual CNC classroom. You can watch demonstrations, follow along with projects, and learn from the experiences of seasoned professionals. Plus, the comment sections often have additional tips and advice from the CNC community. Don’t be afraid to subscribe, comment, and engage with creators. It’s a fantastic way to learn and connect with others who share your passion for CNC.

Forums and Online Communities

Joining forums and online communities is another excellent way to learn about CNC. Websites like CNC Zone, Practical Machinist, and Reddit’s r/CNC are bustling with enthusiasts and experts willing to share their knowledge. These platforms offer a space to ask questions, share projects, and get advice on specific issues you encounter.

Imagine having a global network of CNC enthusiasts at your fingertips. That’s what these online communities offer. You can learn from others’ experiences, find solutions to common problems, and stay updated on the latest trends and technologies. Participating in these forums can significantly enhance your learning journey and provide valuable insights that you won’t find in textbooks.

Books and E-books

If you prefer a more traditional approach, there are plenty of excellent books and e-books on CNC. Titles like “CNC Programming Handbook” by Peter Smid and “CNC Machining Handbook” by James Madison are highly recommended. These books cover everything from basic concepts to advanced techniques, providing a comprehensive understanding of CNC machining.

Think of these books as your CNC bible. They’re packed with detailed explanations, diagrams, and examples that make learning easier. E-books offer the added convenience of being accessible on your device, so you can read and learn on the go. Whether you’re at home, in the workshop, or on a break at work, having these resources at hand can be incredibly beneficial.

Local Workshops and Classes

Local workshops and classes are fantastic for hands-on learning and personal instruction. Many community colleges, technical schools, and makerspaces offer Computer Numerical Control (CNC) courses. These classes often provide access to equipment and materials, allowing you to practice what you learn in real-time.

Imagine being in a room full of CNC machines, with an instructor ready to guide you through each step. These local classes offer a structured environment where you can ask questions, get immediate feedback, and collaborate with fellow learners. The hands-on experience you gain in these settings is invaluable and complements your online and book learning.

Manufacturer Resources

Many CNC machine and software manufacturers provide excellent learning resources. Companies like Haas, Tormach, and Autodesk offer tutorials, user manuals, and support forums. These resources are tailored to their specific products, ensuring you get the most out of your equipment and software.

Think of manufacturer resources as the insider’s guide to CNC. They offer detailed instructions and tips directly from the creators of the tools you’re using. Exploring these resources can help you understand your equipment better, troubleshoot issues, and maximize your productivity. Don’t overlook the wealth of information provided by manufacturers.

CNC Simulation Software

CNC simulation software is a great tool for learning and practicing without risking damage to actual materials or machines. Programs like Fusion 360, Mastercam, and CNC Simulator Pro allow you to create and test G-code in a virtual environment. This hands-on practice helps you understand the machining process and refine your skills.

Imagine being able to test your CNC programs in a risk-free environment. That’s what simulation software offers. You can see exactly how your machine will behave, identify potential problems, and make adjustments before running the program on a real machine. It’s like having a CNC playground where you can experiment and learn with complete freedom.

Blogs and Online Articles

Blogs and online articles are fantastic for keeping up with the latest trends, tips, and tricks in the CNC world. Websites like CNC Cookbook, Machining News, and Make: Magazine offer a wealth of information. From beginner guides to advanced techniques, you’ll find articles that suit your level and interests.

Think of these blogs as your daily CNC digest. They’re regularly updated with fresh content, ensuring you stay informed and inspired. You can learn about new tools, read reviews, and discover innovative projects. Bookmark your favorite blogs and make them part of your regular reading routine to continually expand your CNC knowledge.

Social Media Groups

Social media groups on platforms like Facebook, LinkedIn, and Instagram are excellent for connecting with other CNC enthusiasts. Groups such as CNC Programming, Machinists, and DIY CNC Projects offer a space to share your work, ask questions, and learn from others.

Imagine having a community of CNC enthusiasts right in your pocket. That’s what these social media groups offer. You can post pictures of your projects, get instant feedback, and even find solutions to problems from experienced members. Joining these groups makes learning interactive and fun, adding a social element to your CNC journey.

Conclusion

Learning Computer Numerical Control (CNC) machining is a rewarding journey filled with endless resources. From online courses and YouTube channels to books, forums, and simulation software, there’s something for everyone. Engage with these resources, practice regularly, and connect with the community. By leveraging these tools, you’ll enhance your skills, gain confidence, and unlock the full potential of CNC machining. Happy learning!